Tesla Model S- A Premium Electric Sedan

Introducing a car so advanced it sets the new standard for premium performance. At the heart of the vehicle is the proven Tesla powertrain, delivering both unprecedented range and a thrilling drive experience. With a rigid body structure, nearly 50/50 weight distribution and a remarkably low center of gravity, Model S offers the responsiveness and agility expected from the world’s best sports cars while providing the ride quality of a sedan.

Tesla’s advanced electric powertrain delivers exhilarating performance. Unlike the internal combustion engine with hundreds of moving pieces that spark, pump, belch, and groan, the Tesla motor has only one moving piece: the rotor. As a result, Model S acceleration is instantaneous, like flipping a switch. Hit the accelerator. In 5.4 seconds, Model S is traveling 60 miles per hour, without hesitation and without a drop of gasoline.

Tesla’s advanced electric powertrain delivers exhilarating performance. Unlike the internal combustion engine with hundreds of moving pieces that spark, pump, belch, and groan, the Tesla motor has only one moving piece: the rotor. As a result, Model S acceleration is instantaneous, like flipping a switch. Hit the accelerator. In 5.4 seconds, Model S is traveling 60 miles per hour, without hesitation and without a drop of gasoline.

The Model S suspension system was developed for the unique architecture of Model S. It works in harmony with the rigid and light Tesla platform to provide precision handling and optimum comfort. Unencumbered by an engine, the lightweight front suspension optimizes wheel control. The rear multi-link suspension is designed to seamlessly integrate with the powertrain.

Model S Performance takes electric performance to the next level. Equipped with the 85 kilowatt-hour battery and a high performance drive inverter, Model S Performance accelerates to 60 miles per hour in 4.2 seconds. If driven the same way as Model S, both cars achieve the same efficiency thanks to the unique powertrain design.

Performance Plus takes one of the world's best sedans into supercar handling territory, while also improving ride quality and range. After hundreds of iterations affecting every detail of the suspension, our vehicle dynamics team was able to achieve the rare outcome of simultaneously improving performance, comfort and efficiency. In addition to upgraded dampers, bushings, stabilizer bars and tires (Michelin Pilot Sport PS2), the rear tires are 20 mm wider and staggered for improved acceleration on low grip surfaces.

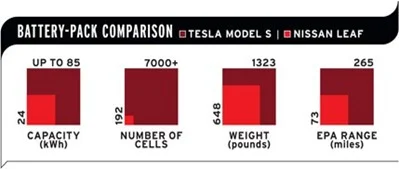

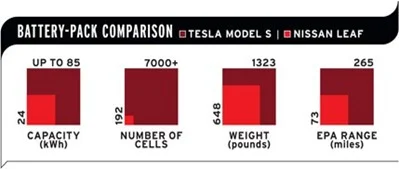

Model S sets the bar for electric driving range. Model S is offered with three battery options, each delivering unprecedented range. All three batteries are contained within the same enclosure, integrating with the vehicle in the same way, providing structural, aerodynamic, and handling advantages. All three batteries use automotive-grade lithium-ion cells arranged for optimum energy density, thermal management, and safety.

Model S sets the bar for electric driving range. Model S is offered with three battery options, each delivering unprecedented range. All three batteries are contained within the same enclosure, integrating with the vehicle in the same way, providing structural, aerodynamic, and handling advantages. All three batteries use automotive-grade lithium-ion cells arranged for optimum energy density, thermal management, and safety.

Model S comes standard with everything you need to plug into the most common 240-volt outlet, standard 120-volt wall outlets and public stations. Using a high-amperage 240-volt outlet, Model S can be recharged at the rate of 100 km range per hour. A fifty-percent charge in thirty minutes can be achieved with a Tesla Supercharger.

Ask Tesla owners how long it takes to charge and they'll say just a few moments. Like they do with a cell phone, most Tesla owners plug in at night. By morning, their battery is completely recharged.

As you approach, the Tesla key commands the door handle to unlock, waiting for a simple tap to present itself. With it in your pocket, Model S turns on as you buckle in to the driver’s seat. The touchscreen, digital instrument cluster, and steering wheel controls seamlessly integrate media, navigation, communications, cabin controls and vehicle data. From the moment you open the door, the high-resolution Model S touchscreen powers on and returns to its last function. The most commonly used controls line the bottom of the screen for easy access any time and connectivity keeps you connected while on the go.

As you approach, the Tesla key commands the door handle to unlock, waiting for a simple tap to present itself. With it in your pocket, Model S turns on as you buckle in to the driver’s seat. The touchscreen, digital instrument cluster, and steering wheel controls seamlessly integrate media, navigation, communications, cabin controls and vehicle data. From the moment you open the door, the high-resolution Model S touchscreen powers on and returns to its last function. The most commonly used controls line the bottom of the screen for easy access any time and connectivity keeps you connected while on the go.

With the All Glass Panoramic Roof, Model S is the only sedan capable of delivering a convertible-like drive experience every day. It's more than a sunroof: the entire roof is constructed from lightweight safety glass. With a simple swipe of the Touchscreen, it opens wider than any other sedan's panoramic roof. On even the hottest days, the innovative glass keeps the cabin comfortable.

Model S is a driver’s car. Behind the wheel, you’ll notice that Tesla has combined meticulous noise engineering with Tesla’s uniquely quiet powertrain to obtain the sound dynamics of a recording studio. The gem of the interior is the 17” touchscreen. It puts rich content at your fingertips and provides mobile connectivity.

With no tailpipe to spew harmful emissions, Tesla vehicles liberate their owners from the petroleum-burning paradigm. They are the only cars to getmore efficient from the moment they're first driven.

Gasoline-powered vehicles and hybrids burn refined petroleum. Tesla vehicles can use electricity however it is produced, be it from coal, solar, hydro, geothermal, or wind power. As the grid shifts to increasingly efficient technologies, Tesla owners reap the efficiency benefits.

Dimensions

- Head room (front/rear): 38.8/35.3"

- Leg room (front/rear): 42.7/35.4"

- Shoulder room (front/rear): 57.7/55.0"

- Hip room (front/rear): 55.0/54.7"

- Seating capacity: 5 adults

- Total cargo volume: 31.6 cu ft

- Rear cargo volume (seats up/down): 26.3/58.1 cu ft

- Front trunk cargo volume: 5.3 cu ft

- Turning circle: 37 ft

- Curb weight: 4,647.3 lbs

- Weight distribution (%, front/rear): approx. 48/52

Body

- Lightweight aluminum body reinforced with high strength, boron steel elements

- UV and infrared blocking safety glass windshield

- Rain sensing, adjustable speed windshield wipers

- Frameless, tempered safety glass front windows

- Solar absorbing, laminated safety glass rear window with defroster

- Flush mounted door handles

- Manual folding side mirrors

- 19" aluminum alloy wheels with all-season tires (Goodyear Eagle RS-A2 245/45R19)

- Aluminum roof

- Xenon headlights with automatic on/off

- Backlit side turn signals, front side marker lights and rear reflex lights

- LED rear taillights and high-mounted LED stop lamp

Powertrain

- Model S is a rear wheel drive electric vehicle. The liquid-cooled powertrain includes the battery, motor, drive inverter, and gear box.

- 60 kWh microprocessor controlled, lithium-ion battery

- Three phase, four pole AC induction motor with copper rotor

- Drive inverter with variable frequency drive and regenerative braking system

- Single speed fixed gear with 9.73:1 reduction ratio

Suspension, Steering, and Brakes

- Double wishbone, virtual steer axis coil spring front suspension and independent multi-link coil spring rear suspension

- Variable ratio, speed sensitive, rack and pinion electronic power steering

- Electronic Stability Control

- Traction Control

- Anti-Lock disc brakes (ABS) with ventilated rotors and electronically actuated parking brake; front: 355 mm x 32 mm; rear: 365 mm x 28 mm

Charging

- 10 kW capable on-board charger with the following input compatibility: 85-265 V, 45-65 Hz, 1-40 A (Optional 20 kW capable Twin Chargers increases input compatibility to 80 A)

- Peak charger efficiency of 92%

- 10 kW capable Universal Mobile Connector with 110 V, 240 V, and J1772 adapters

Interior

- Twelve way, power adjustable, heated front seats

- Hand wrapped microfiber and synthetic leather interior surfaces in black

- Piano black décor accents

- Center armrest with two cup holders

- Open center console storage area

- Metal interior door handles

- 60/40 split fold-down second row seats

- 200 watt, seven speaker stereo system with AM/FM/HD radio. Supports MP3, AAC, and MP4 music formats. System includes four speakers, two tweeters and one center channel speaker.

Instrumentation

- 17" capacitive touchscreen with media, communication, cabin, and vehicle controls

- Bluetooth wireless technology for hands-free calling and streaming music

- Three spoke, multi-function steering wheel with tactile controls

- Tire pressure monitoring system

Warranty

- 4 year or 50,000 mile, whichever comes first, new vehicle limited warranty

- 60 kWh battery has an 8 year or 125,000 mile, whichever comes first, warranty

- 85 kWh battery has an 8 year, unlimited mile warranty

Convenience

- Keyless entry

- Driver seat detection sensor for start/stop functionality

- Cruise Control

- High definition backup camera

- Manual rear liftgate

- Power tilt and telescopic steering column

- Power windows featuring one-touch up and down with resistance reversing to protect against pinched fingers

- Micro-filter ventilation system with replaceable filters

- Front LED map lights and rear LED reading lights

- Front sun visors

- Front trunk and rear cargo area with keyless open

- 12 V power outlet

- Automatic climate control with dual zone temperature settings, air distribution controls and recirculation

- Glove compartment

- Wi-Fi ready

- Dual front USB ports for media and power

Safety

- Eight airbags: head, knee and pelvis airbags in the front plus two side curtain airbags

- Driver and front passenger seat sensors

- Driver seat position sensor

- Three point driver and front passenger safety belts with retractor pretensioners and secondary lap anchor pretensioners and load limiters

- Three point second row safety belts for all three seats

- Acoustic front row safety belt warning

- Rollover crash sensor

- Crash sensor for high voltage disconnect

- Three second row LATCH attachments for child seat installations (accommodates three child seats simultaneously: two with LATCH and one with top tether and belt)

- Rear door child safety locks

- Interior, manual release mechanism for all doors, front trunk, and rear cargo area

- Anti-theft alarm and immobilizer system

- Horn. Beep. Beep.

Model S sets the bar for electric driving range. Model S is offered with three battery options, each delivering unprecedented range. All three batteries are contained within the same enclosure, integrating with the vehicle in the same way, providing structural, aerodynamic, and handling advantages. All three batteries use automotive-grade lithium-ion cells arranged for optimum energy density, thermal management, and safety.

Model S sets the bar for electric driving range. Model S is offered with three battery options, each delivering unprecedented range. All three batteries are contained within the same enclosure, integrating with the vehicle in the same way, providing structural, aerodynamic, and handling advantages. All three batteries use automotive-grade lithium-ion cells arranged for optimum energy density, thermal management, and safety.